R4 Flex Putty

High-Strength Cement-Based Mortar for Crackless Smoothing & Structural Strengthening

Two-Component, Water-Impermeable & High-Ductility Solution for Concrete, Stone & Masonry Surfaces

Ideal for seismic reinforcement, leveling & mesh laying--easy to mix, strong adhesion, long-lasting performance.

≥30 N/mm²

Compressive

Key Features & Benefits

Advanced cement-based mortar technology delivering superior performance for demanding construction applications

Crackless Application

No cracks after curing, stable performance in various environments and weather conditions

High Bonding Strength

Adheres firmly to concrete, stone, brick & tuff surfaces (≥2.5 N/mm² after 28 days)

Water & Gas Impermeable

Resists water penetration and aggressive atmospheric gases for long-term protection

Easy Mixing

Mixes with potable water--mechanical mixing ensures homogeneity with no lumps

High Ductility

Suitable for structural strengthening & seismic stress resistance applications

Versatile Use

For smoothing, leveling, mesh laying & masonry reinforcement applications

Applications & Use Cases

Versatile structural strengthening mortar for professional construction applications

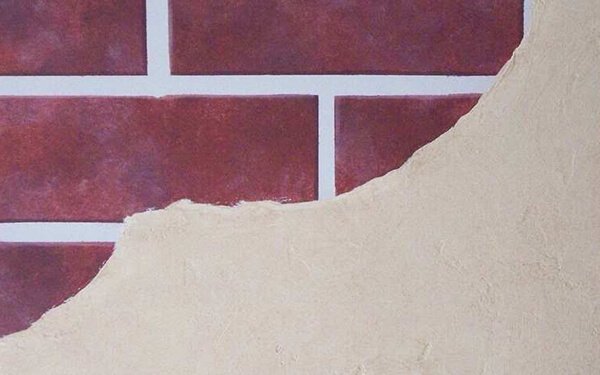

Smoothing & Leveling

Concrete, stone, brick & tuff surfaces preparation for final finishes

Structural Strengthening

Facing walls, ceilings, masonry elements reinforced with glass fiber mesh

Seismic Reinforcement

Resists stresses from seismic activity using advanced mesh laying system

Masonry Repair

Leveling & strengthening of stone/brickwork structures and heritage buildings

Technical Specifications

Comprehensive technical data for R4 Flex Putty cement-based mortar specifications

| Parameter | Details |

|---|---|

| Type | Two-component cement-based mortar (powder + liquid admixture) |

| Pot Life of Mix | 30 minutes |

| Max Thickness per Coat | 6 mm (single layer) |

| Application Temperature | +5°C ~ +35°C |

| Setting Time (23°C, 50%RH) | Beginning > 4 hrs; Ending < 9 hrs |

| Compressive Strength | >5 N/mm² (1 day); >20 N/mm² (7 days); >30 N/mm² (28 days) |

| Flexural Strength | >1.5 N/mm² (1 day); >6 N/mm² (7 days); >9 N/mm² (28 days) |

| Adhesion to Concrete | >2.0 N/mm² (7 days); >2.5 N/mm² (28 days) |

| Dosage | 1.0-1.5 kg/m² per mm of thickness |

| Packaging | 22 kg kit (20kg Component A Powder + 2kg Component B Liquid) |

| Shelf Life | Component A: 12 months; Component B: 24 months (dry storage ≥+5°C) |

Application & Mixing Guide

Step-by-step R4 Flex Putty mixing instructions and wall putty application guide

Surface Preparation

Clean, sound substrate (remove dust/oil/old paint); wet until saturated (no standing water)

Mixing

Add Component B (liquid) + 6L water → slowly add Component A (powder) → mechanical mixing (no hand mixing) → homogeneous mixture (no lumps)

Application for Mesh Laying

1st layer (0.8-1.5mm) → press mesh → 2nd layer (2-3mm, cover mesh) → smooth while fresh; mesh overlap ≥5cm

Application as Smoothing Layer

Spread up to 6mm thickness → smooth with metal trowel; use R2 Finish Coat for smooth finish

Curing

Protect from quick evaporation (dry/hot/windy conditions); cure at ≥+5°C

Usage Precautions

Do not apply at temperature <+5°C

Do not add cement/aggregates to the mix

Cure carefully in dry/hot/windy environments (prevent water evaporation)

Store components at ≥+5°C (original packaging, dry place)

Request a Quote for R4 Flex Putty

Get professional pricing for high-quality cement-based mortar solutions

We will respond within 24 hours. For urgent inquiries, call +86 20 6106 9818