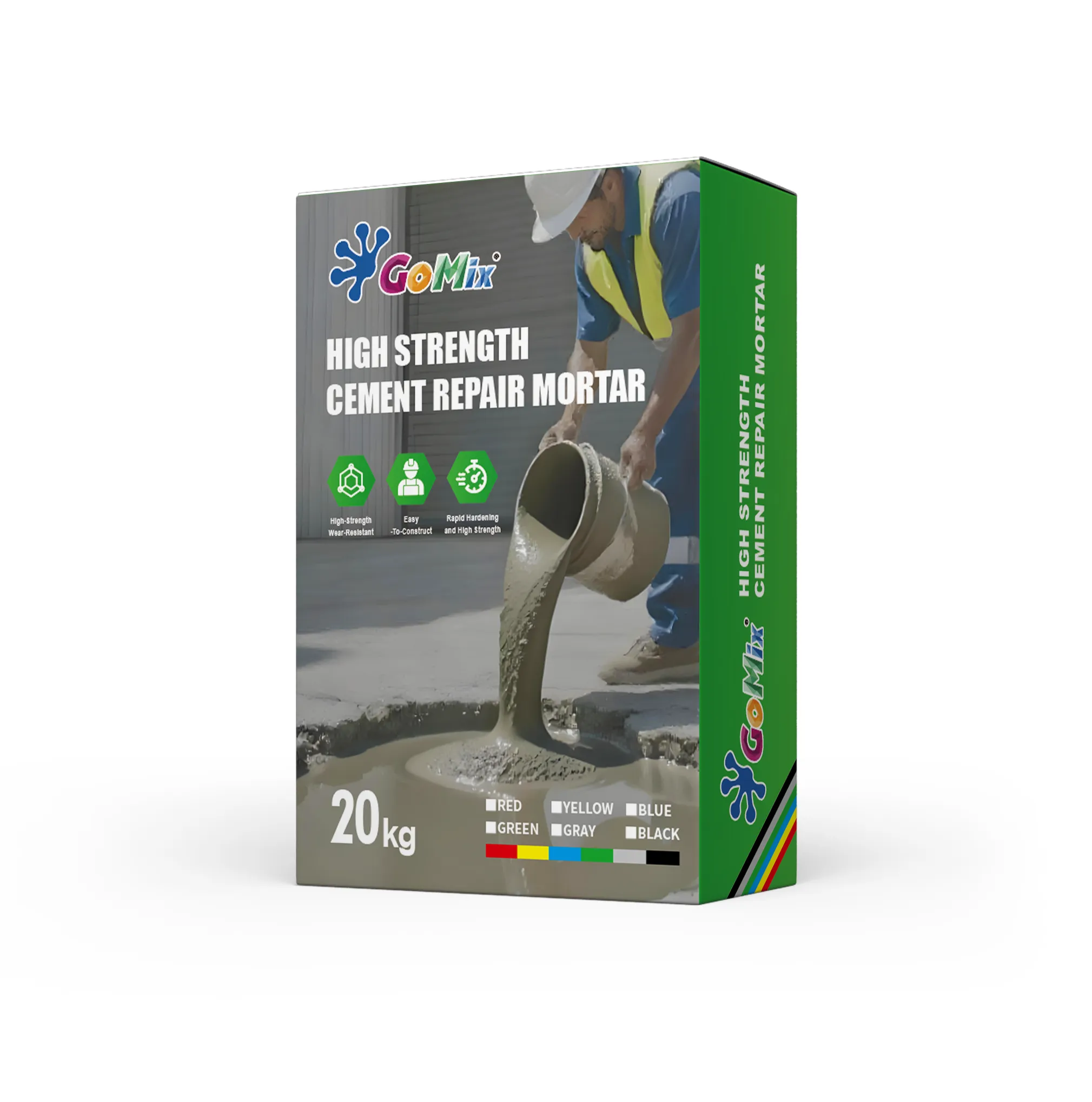

SL10 Self Levelling High Strength Cement Repair Mortar

Quick-Drying Floor Repair Compound

Fix Cracks, Pits & Level Floors in 2 Hours - 2-3x Stronger Than Ordinary Cement

1H Pedestrian Traffic

2H Vehicle Traffic

No Curing Needed

(Below 25℃)

Just Add Water

Easy Construction

Acid & Alkali Resistant

Frost Proof

Professional Grade

Suitable for industrial & commercial applications

Solve Your Floor Repair Problems Efficiently

Stop wasting time and money on temporary fixes. Our SL10 cement repair mortar addresses the root causes of floor damage.

❌ Floor Cracks & Pits

Concrete floors develop cracks and holes over time, creating safety hazards and reducing operational efficiency.

✅ High Adhesion & Compressive Strength

28-day strength ≥60MPa - directly repair without redoing foundation. Permanent solution that bonds seamlessly with existing concrete.

❌ Time-Consuming Construction

Traditional repair methods require specialized skills, multiple steps, and extended downtime affecting business operations.

✅ Quick-Drying (Initial Set in 2H)

No professional experience needed. Simple mix-and-pour process gets your floor back to service in just 2 hours.

❌ Poor Durability

Weather exposure and chemical corrosion cause repairs to fail quickly, requiring constant maintenance.

✅ Sun Protection, Frost & Chemical Resistance

Engineered to withstand extreme weather, acid/alkali exposure, and heavy traffic loads for long-lasting performance.

❌ Uneven Floors

Manual leveling is inconsistent and labor-intensive, often resulting in uneven surfaces that affect equipment operation.

✅ Self-Levelling (120-130mm Flow-ability)

Automatically flows to create perfectly level surfaces. Precision leveling without manual effort or rework.

❌ Long Downtime

Extended curing times mean facilities remain out of service for days or weeks, causing significant revenue loss.

✅ 2H Vehicle Traffic Ready

Resume full operations quickly. Pedestrian traffic in 1 hour, vehicle traffic in 2 hours. Minimize business disruption.

Why Choose SL10 Cement Repair Mortar?

Engineered for professional contractors and facility managers who demand reliable, high-performance solutions.

Pre-mixed Dry Composite

Ready-to-use, just add water (3.3-3.6L/20kg). No extra additives required. Consistent quality every time.

→ Simplified ConstructionHigh Strength Performance

2h Compressive Strength ≥25MPa, 28d ≥60MPa. Equivalent to 2-3x ordinary cement strength.

→ Superior DurabilitySuper Fluidity

Self-levelling with 120-130mm flow-ability. Smooth finish without reworking or manual leveling.

→ Perfect FinishQuick Construction

Mixed material usable within 5 minutes. Simple operation suitable for beginners and professionals.

→ Fast ApplicationWide Application

Perfect for industrial plants, warehouses, parking lots, airports, highways, schools, and communities.

→ Versatile SolutionCustom Color Available

Grey, Green, Red, Blue Yellow,Black. OEM service available for special color requirements.

→ Brand CustomizationNon-toxic & Eco-friendly

Safe for indoor/outdoor use. High adhesion without peeling. Environmentally responsible formula.

→ Safe & SustainableTechnical Specifications

Detailed performance data and application parameters for professional specification writers and contractors.

| Item | Specification |

|---|---|

| Product Name | Self Levelling High Strength Floor Repairing Compound |

| Country of Origin | China |

| Package | 20KG/Bag |

| Coverage | 3-4 M²/Bag@3mm thickness |

| Compressive Strength | 2h ≥25 MPa; 28d ≥60 MPa |

| Flexural Strength | 2h ≥8 MPa |

| Flow-ability | 120-130mm |

| Tensile Strength | ≥1 MPa |

| Water Ratio | 3.3-3.6L/20kg Powder |

| Pedestrian Traffic | 1H After Construction |

| Vehicle Traffic | 2H After Construction |

| Application Tools | Steel Float or Trowel |

| Application Temperature | Above 5-35℃ |

Widely Used In Various Scenarios

From heavy industrial facilities to decorative community spaces, SL10 adapts to your specific application needs.

Industrial Plants

Repair pitted/cracked concrete floors in manufacturing facilities

Warehouses & Logistics

High-load bearing floor levelling for storage facilities

Parking Lots & Gas Stations

Anti-slip, corrosion-resistant finish for vehicle areas

Airports & Highways

Rapid patching for emergency maintenance operations

Schools & Playgrounds

Safe, non-toxic, custom color options (Red/Blue)

Communities & Traffic Lanes

Seamless repair with long-lasting durability

Courtyards & Roofs

Grey color, weather-resistant for outdoor applications

Custom Applications

Contact us for specialized requirements and OEM solutions

Simple Construction Steps

Professional results with minimal experience required. Follow these 6 simple steps for perfect floor repair.

Clean & Soak

Remove debris, rinse with high-pressure water, soak for 1-2h until no visible water remains on surface.

Prepare Mix

Add 3.3-3.6L water per 20kg powder. Mix thoroughly with electric drill for uniform consistency.

Pour Material

Pour mixed compound into repair area immediately. Work quickly as material begins setting within 5 minutes.

Smooth Quickly

Level with trowel once. No reworking before solidification. Self-levelling properties ensure smooth finish.

Cure (If Needed)

Water curing on day 2-3 when temperature >25℃. Below 25℃ requires no additional curing process.

Ready to Use

Pedestrian traffic in 1h, vehicle traffic in 2h. Fast return to service with minimal downtime.

Frequently Asked Questions

Get answers to common technical questions about SL10 cement repair mortar application and performance.

Why are there fuzzy things on the finished floor?

Fuzzy appearance typically results from improper surface preparation or mixing ratios. Ensure the substrate is thoroughly cleaned and properly dampened. Use exact water ratios (3.3-3.6L per 20kg) and mix uniformly. Avoid overworking the surface after application. For technical support on surface preparation, contact our team.

Why does the floor have color patches after construction?

Color variations occur due to uneven moisture content in the substrate or inconsistent curing conditions. Ensure uniform substrate moisture before application. Maintain consistent ambient temperature and humidity during curing. For large areas, work in sections with wet edges to avoid visible joints. Our quality control ensures batch-to-batch color consistency.

Why does the floor peel or shell?

Peeling results from poor substrate adhesion due to contamination, dust, or insufficient surface preparation. Remove all loose material, oil, and debris before application. The substrate must be structurally sound and properly dampened. SL10's high adhesion formula (≥1 MPa tensile strength) prevents peeling when applied correctly. Avoid application on frozen or extremely hot surfaces.

How to ensure consistent color between batches?

We maintain strict quality control with automated batching systems and color matching protocols. Each production batch undergoes color verification testing. For large projects requiring multiple batches, order sufficient quantities from the same production run. Store materials in consistent conditions and use identical mixing procedures. OEM color matching services available for specific requirements.

Can it achieve C50-C60 strength as advertised?

Yes, SL10 consistently achieves ≥50 MPa compressive strength at 28 days when applied according to specifications. Our formulation includes high-performance additives and carefully graded aggregates. Third-party test certificates available upon request. Strength development continues beyond 28 days. Proper mixing ratios, application temperature (>0°C), and curing conditions are critical for achieving specified performance.

What's the application temperature range?

Application temperature must be above 0°C (32°F) for proper curing. Optimal range is 5-35°C (41-95°F). Below 25°C, no additional curing is required. Above 25°C, provide water curing on days 2-3. Avoid application in direct sunlight on hot days or when rain is expected within 2 hours. For extreme temperature conditions, consult our technical team for specific recommendations.

Have more technical questions?

Trusted by Clients Worldwide

See how SL10 cement repair mortar has solved critical floor repair challenges across different industries and regions.

Industrial Warehouse - Germany

Manufacturing Facility Floor Crack Repair

"Severe floor cracking in our 15,000 m² facility was affecting production equipment alignment. SL10's high compressive strength and self-leveling properties provided a permanent solution. No downtime beyond the 2-hour curing period."

Challenge: Heavy machinery causing floor stress cracks

Solution: 850 bags SL10, 2-day completion, zero operational disruption

Parking Lot - USA

Rapid Levelling & Patching Project

"Shopping center parking lot had multiple potholes and uneven surfaces creating liability issues. SL10's quick-drying formula allowed us to complete repairs during overnight hours without affecting business operations."

Challenge: Minimize disruption to retail operations

Solution: 320 bags SL10, overnight application, ready for morning traffic

School Playground - Australia

Custom Red Color Floor Installation

"Required safe, non-toxic flooring for children's play area with specific red coloring to match school branding. SL10's custom color service and eco-friendly formula made it the perfect choice for this sensitive application."

Challenge: Child-safe materials with custom aesthetics

Solution: 180 bags custom red SL10, non-toxic certification provided

Airport Maintenance - Canada

Emergency Runway Patch Repair

"Critical runway surface damage required immediate repair during limited maintenance window. SL10's 2-hour vehicle traffic readiness enabled us to restore full airport operations within schedule constraints."

Challenge: Critical infrastructure with zero tolerance for delays

Solution: 450 bags SL10, 4-hour maintenance window, full strength achieved

Request a Custom Quote

Tell us your project details, we'll get back to you within 24 hours with a comprehensive quote and technical recommendations.

Contact Information

info@gomixhk.com

WhatsApp/WeChat

+86-13728687749

Office Locations

Hong Kong, Guangzhou, Shenzhen, Dongguan, Foshan, Huizhou PR China

Quick Response Guarantee

Our technical team responds to all quote requests within 24 hours with detailed specifications and pricing.

Free Technical Support

Get expert guidance on application methods, quantity calculations, and project planning.